How an alternator's AC output is converted into DC voltage your car can use

Most of you drive cars everyday; commuting to work, running errands, what-have-you. Maybe some of you don't. Maybe you have chauffeurs carting you around while you contemplate the finer things in life, like what it would be like to own a private jet with a big picture of yourself painted on the side. This does not concern you. I'm just going to explain how an alternator works.

This isn't meant to be exhaustive, just a basic overview. An alternator is the primary source of electricity in a vehicle when the engine is running. It converts AC into DC using a rectifier bridge.

An alternator is essentially an electromagnetic generator connected to an array of diodes, known as a rectifier bridge. It has three sets of wire coils, known as stators, within which a magnet rotates. As the magnet rotates, it's magnetic field affects each of the stators in turn, generating an AC voltage based on the polarity of the magnet. Rotating the magnet within any one of these stators will generate a near-perfect sine wave with a frequency in Hertz (cycles per second) matching the number of times the magnet rotates per second. In other words, each one will produce a positive voltage and a negative voltage for each full rotation of the magnet.

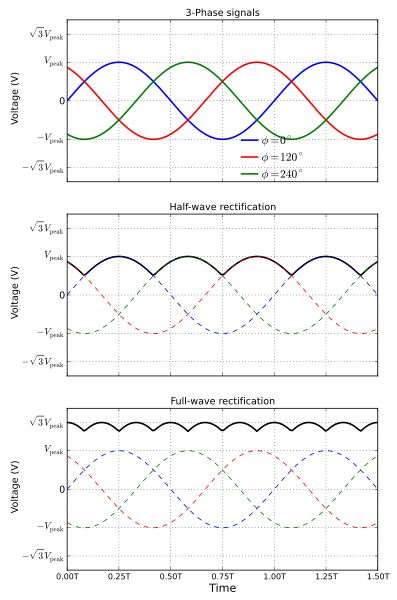

Here's the cool part: Each of those coils is offset from the next by 120 degrees along the axis of the magnet, so each sine wave produced by each coil sort of "fills in the gaps" left by the other two. When the engine is running, the alternator is producing what is known as three-phase AC. That's where the rectifier bridge comes in. The rectifier bridge is a series of diodes, which only pass the positive portion of each AC wave. Since there are three waves, the now-DC voltage produced is just the positive voltage along the "peaks" of each wave, as seen on the right. This is called "three-phase ripple" DC. Sometimes a capacitor is used to further smooth out this voltage. Think of a capacitor like a reservoir behind a dam. The dam can always produce a consistent amount of power, because there is enough water in the reservoir to keep the turbines running, without being directly dependent on the rate of flow of the actual water source. Once the reservoir is empty though, it will still need to be refilled. It works the same way here. Each little "dip" in the ripple DC is lessened by the capacitor.

Without getting into the physics behind it, that's about it. All the DC electronics in your car run off of an AC power supply, thanks to a few diodes.

This is some nice trivia for your typical car owner, but what can we actually DO with this info?

For people looking to make electrical upgrades to their vehicles, understanding how an alternator does what it does isn't critical, until it comes to troubleshooting. Like any other vehicle components, alternators can have parts fail. Unlike many other car components, your alternator can suffer a partial failure, while not completely failing to do it's job. Your car might still start and drive as usual, but the electrical system might be weak. Relatively quiet music can cause headlights to dim if you have an amplified audio system installed. You might buy three new car batteries in a year because the faulty alternator is not maintaining their charge properly. If you are adding to or modifying anything in a cars electrical system , it's not a bad idea to check the alternator for two main things.

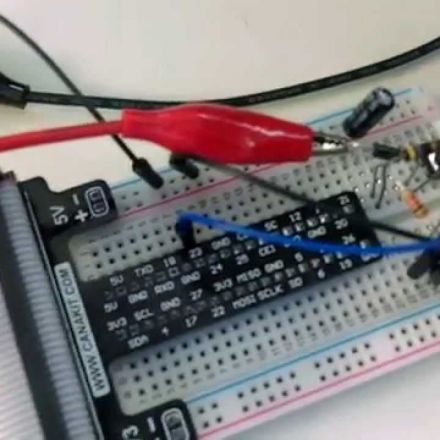

First, test the output voltage of the alternator to ensure it is functioning properly. Using a digital multimeter set to DC voltage, place the positive (red) testing probe on the alternator's output wire, and the negative (black) probe to a good ground point, ideally the negative pole on the vehicle's battery. If the voltage is less than 13 volts, or fluctuates rapidly, it could be a sign of alternator problems.

Secondly, make sure the alternator can provide the additional current needed for the application. As a general rule of thumb, if you are going to be drawing 120% or more of an alternators rated output amperage, consider upgrading it. Keep in mind that included in that 120% is the amount of current the rest of the car needs to function. Depending on the vehicle, this could be anywhere from around 40 amps up to 90 amps or more.

There are other important concerns when it comes to a vehicle's electrical system, not the least of which is the importance of properly grounding electrical components, something which isn't always done correctly, even right off the factory floor. However, that's a post for another day. Hope you guys found this interesting, feel free to hit me up with questions or corrections. I suppose I'll also throw in another shameless plug for /t/audiotechs. I mostly do mobile audio, but I'm starting to branch out and hoping to develop a forum encompassing a broad range of audio and electronics interests.

Cheers.

-

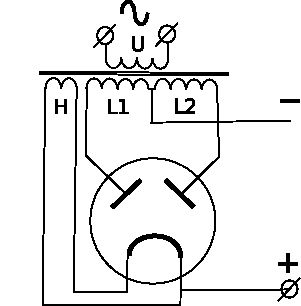

One half of an alternator. The coils of wire around the perimeter form the stators, and each of those little guys in the center connected to a wire is a diode. The other half you don't see holds the rest of the housing containing the magnet, which is connected to a pulley run by the engine belt.

One half of an alternator. The coils of wire around the perimeter form the stators, and each of those little guys in the center connected to a wire is a diode. The other half you don't see holds the rest of the housing containing the magnet, which is connected to a pulley run by the engine belt.

-

Three-phase ripple AC and the effect of the rectifier bridge.

Three-phase ripple AC and the effect of the rectifier bridge.

-

This is a circuit diagram for a rectifier that uses a vacuum tube. It has absolutely nothing to do with how an alternator works, but I'm posting it here because it reminds me of that one scene in A Clockwork Orange. You know the one.

This is a circuit diagram for a rectifier that uses a vacuum tube. It has absolutely nothing to do with how an alternator works, but I'm posting it here because it reminds me of that one scene in A Clockwork Orange. You know the one.

Join the Discussion

Great info to know. Maybe next time I'll install everything myself instead of paying a pro to do it.

An alternator swap isn't too hard, provided the alternator isn't physically located in a difficult-to-access area . Disconnect your battery wires (I usually tape off the ends just to be on the safe side), then the alternator wires. Somewhere in the belt system there will usually be a tensioner spring attached to a pulley that you can loosen to get the belt off. After that, you just unbolt the old alternator, bolt on the new one, and reverse the process.