The Challenge and Option of PCB Heatsink

-

The Challenge and Option of PCB Heatsink

PCB warm sink for snap-in transistor preserving springtimes The different geometries of the PCB heatsink consist of a threaded channel currently incorporated right into the extrusion procedure, through which the private heat sink can be screwed to the motherboard.

The simplification of transistor setting up is made sure for the numerous kinds of printed circuit board warmth sink by means of a special groove geometry incorporated into the warmth sink and also snap-in transistor retaining springs made of stainless-steel. As soon as engaged, the springtime remains in place as well as solutions the transistor with high call pressure on the installing surface.

PCB heatsink The demands for motherboard air conditioning have never been as high as they are today: The raising combination thickness during assembly and the range of real estate designs utilized position significant difficulties for developers. The CTX Thermal Solutions GmbH provides a wide variety of PCB heat sink, tailored to the various types of PCB setting up, to dissipate the heat rapidly and dependably.

Despite whether it is an office, household or plant innovation: The cooling of electronic settings up is important for their error-free and also durable feature. CTX has a number of numerous designs of PCB heatsink with thermal resistance worths between 6 as well as 72 ° C/ W in the basic array. Efficiently matched to the corresponding application and also sort of assembly, they guarantee dependable cooling. If a basic option is not the ideal choice, CTX establishes the application-specific heat sink along with the client-- made to determine making use of CNC modern technology as well as based on thermal simulation.

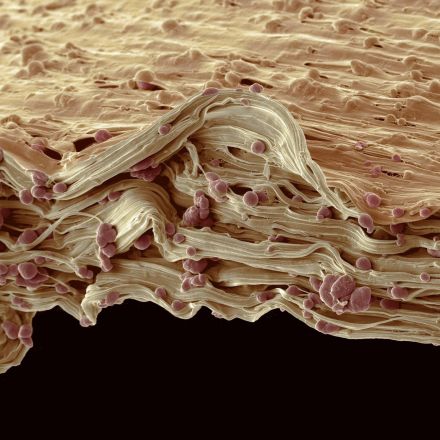

The difficulty of PCB heatsink Journalism of the motherboard with the warmth sink ends up being an obstacle in both processes. The areal distribution of the thermal adhesive without air pockets in between the two parts was formerly an unresolved trouble and is specifically due to the reduced circulation properties of the thermal adhesive. An adequate distribution was accomplished by pressing on with supposed stress pins, however this technique is only suitable to a restricted level. The outcome was commonly that, particularly when it comes to slim and large-area ceramic substratums, the prompt and also thus too much pressure action led to the ceramic board breaking.

The remedy for MOKO PCB Assembly Dow Corning, an international manufacturer of reliable thermal adhesive, was looking for an extra innovative as well as a lot more affordable service. The vacuum cleaner signing up with procedure specifically created by Scheugenpflug AG consists of all needs and also offers a process-reliable outcome.

After the adhesive bead has actually been put on the heat sink as well as the motherboard has actually been joined, the unassembled component is assisted right into a mini vacuum cleaner chamber. Because of the tiny size of the vacuum box (15 x 12 x 7 centimeters ³), the emptying and also subsequent ventilation take only a fraction of a second. When evacuating, all air, consisting of that in between the tracks of the glue beads or between the warmth sink as well as the motherboard, is totally gotten rid of. When venting, the quickly boosting air pressure suggests that the board is pushed uniformly. The gap dimension is defined by including bigger solids in the adhesive. These are distributed homogeneously in the thermal adhesive as well as establish the gap size over the whole area of the board. Subsequently, the void range is specified based on the size of the solid.

Nonetheless, not all dosing systems appropriate for this application. Piston dispensers that are developed for big grain sizes and also can refine also extremely filled up and also abrasive adhesives in lasting usage are suitable.

Join the Discussion