Taking Care Of PCB Rework Properly is Much Better Than Discarding Them

In times of difficulty to obtain components, increasing need for versatility and fast advancement cycles, tidy and economical PCB rework to conserve set up or bare published motherboard are coming to be increasingly essential.

-

Taking Care Of PCB Rework Properly is Much Better Than Discarding Them

In times of difficulty to obtain components, increasing need for versatility and fast advancement cycles, tidy and economical PCB rework to conserve set up or bare published motherboard are coming to be increasingly essential. Every PCB or PCB setting up that can be fixed by rework secures our environment by not getting rid of it and also by not needing to generate new PCBs. Bauer Express PCBs have conserved greater than 500,000 PCBs in the last few years.

Utilizing unique, self-developed strategies, the professionals at MOKO Technology can, for instance, drill holes right into formerly put together assemblies. The accuracy represents the freshly generated published circuit card The job is only executed by workers with several years of experience in PCB fabrication. Advanced gauging modern technology makes it possible for optimum monitoring of the work. Depending on the amount and complexity of the rework, the shipment time is usually less than 5 working days after invoice of the goods. An express solution is likewise readily available for immediate PCB remodel, where it is feasible to accomplish revamping within a few hours.

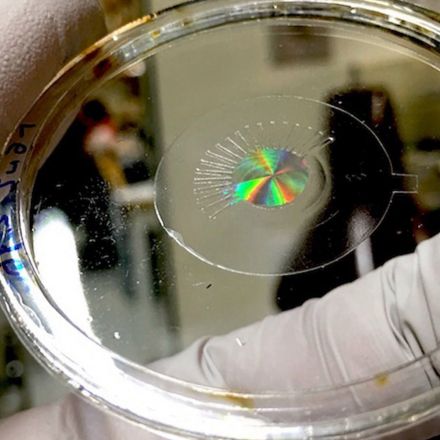

PCB Rework put together boards. PCB rework

Unsolder and after that solder in again In order to solve the unique issues to the contentment of clients in the long-term, MOKO Innovation has purchased tools. The focus right here was on basic and gentle material elimination and also re-soldering of components. The selection fell on the Ersascope 1 as well as the PCB rework system IR 550 A from Kurtz Ersa. At MOKO Technology, particular care was taken to make sure that the circuit card was heated as homogeneously as feasible. We maintain the thermal anxiety on the boards as reduced as feasible during the PCB revamp procedure. Therefore, we do not needlessly impair the lifespan of the published circuit boards and elements. The repair service and reconditioning after that happen both manually and also with mechanical assistance.

The IR 550 A rework system heats up the PCB homogeneously utilizing medium-wave infrared emitters (4 µm to 8 µm). Warming up the setting up is important to stop the PCBs from contorting as well as to attain a low-temperature gradient ΔT from the top of the PCB to the bottom.

The leading heating in the Ersa systems is likewise created as a medium-wave infrared heater or hybrid heater. The hybrid heater is an infrared heating system with a low degree of convection. By doing this we can also attain a reduced horizontal temperature level gradient, i.e. throughout the element, from edge to corner. Additionally, we avoid hot spots as a result of excessive hot air as well as decrease the surprising of surrounding, unsecured elements.

Automated desoldering during PCB rework In every procedure throughout PCB remodel, a sensing unit records the temperature level straight on the component. A closed control loophole controls and regulates the soldering process, which ought to minimize the danger of temperature deviations and the connected anxiety for the components and also motherboard. Our employees also work in a regulated manner when picking up parts from the circuit card. The IR 550 A from Kurtz Ersa is furnished with a vacuum cleaner pipette incorporated right into the top radiator. This enables the desoldering process to be automated. The attached vacuum cleaner suction mug instantly raises the part off the board as soon as the solder has thawed. This careful getting the element avoids any kind of tension on the motherboard.

These gentle processes are especially sought after for package-on-package applications. When soldering in and out, the requirements for the homogeneity of the warmth circulation are especially high. For example, both degrees can be edited at the same time. Elements lying one over the various other can be taken off with each other after the solder thaw. The exact same puts on the re-soldering of the components. These can be positioned as well as soldered with each other, which simplifies the overall procedure.

A high degree of know-how and also modern devices are definitely required for the specialist handling of rework. When it comes to special tasks such as package-on-package or wiring under BGAs, tact, experience and the right technological devices are vital. MOKO Printed Circuit Board Assembly has actually been carrying out PCBA and PCB production since 2006, so we're currently really experienced in handling the PCB rework. We validate that special jobs have actually also come near the Chinese experts for many years. Initially, the questions were convenient, yet in time we have actually developed a good reputation for special tasks to make sure that we are handling significantly requiring tasks that have been as well as will be left. Our primary job is not just standard soldering and also re-soldering of elements. We frequently conserve the entire circuit board with our work, which means that our clients can meet their distribution days and

Join the Discussion