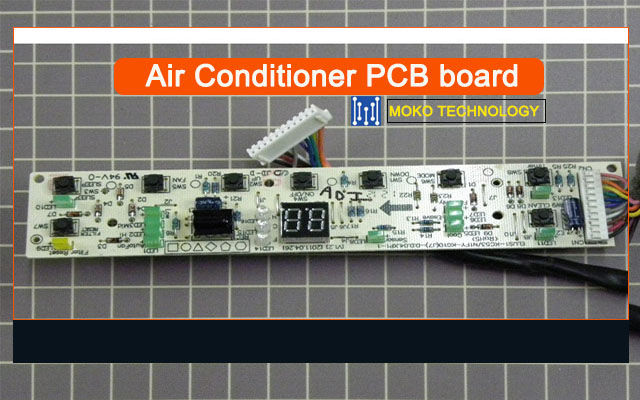

Sensible Alternatives for an Air conditioning unit PCB board

In this section, we will take a short check out several of the viable alternatives which are excellent for usage as an a/c PCB board So, without additional ado, let us study the conversation of readily available options which are both possible and functional.

-

Sensible Alternatives for an Air conditioning unit PCB board

In this section, we will take a short check out several of the viable alternatives which are excellent for usage as an a/c PCB board So, without additional ado, let us study the conversation of readily available options which are both possible and functional.

Choices for an Ac unit PCB board. 1. High Temperature PCB Ac unit PCB board Lay out Capacities PCB board suppliers are attempting their ideal to optimize the performance of their PCBs. We reside in an age where we make increasingly more digital devices each day. Devices such as an air conditioner are infrequent use. So, these devices have high power thickness as well as for this reason they operate on fairly higher temperatures. Thus, we require to observe unique treatment that the dielectrics as well as conducting product we select for our PCB are suitable for the task. When we are handling high temperatures then we reach observe an increase in conducting resistance and for that reason existing losses.

When it comes to a HVAC system such as an air conditioning system, this effect is a lot more noticeable. Consequently, we reach observe a substantial adjustment in resistance residential or commercial properties and also subsequently an extreme change in thermal properties. Therefore, the efficiency of the cooling system could reduce and also might ultimately result in a severe system failure.

If we make use of regular PCBs for usage in air conditioning system after that they might not work well. The primary reason for this is that normal PCBs can not handle the severe temperature changes and as a result they are typically vulnerable to thermal stresses in addition to mechanical stress and anxieties. Thermal tension happens when an item is heated and cooled rapidly with no rest period. This can result in a generation of cracks in the PCB which will ultimately add towards failing. The possibilities enhance substantially if the variety of home heating and also cooling down cycles boosts.

Additionally, if the operating temperature level is large after that the PCB board could melt instantly. Therefore, we require to choose High Frequency PCB because they have great thermal conductivity. This implies that we can use them at really high operating temperature levels and they won't show failure. This is because warmth can conveniently flow through Heat PCB Consequently, these PCBs are indifferent to thermal stresses as well as the subsequent breaking. In addition to that, they are unsusceptible to local heating sensation since warm is equally and also evenly distributed in a High Temperature PCB

- High Frequency PCB. A lot of a/c today are usually part of clever home systems. This means that you can control their cooling temperature level by using the dedicated remote. Nevertheless, some smart air conditioners even allow you to regulate their cooling temperature as well as other performance specifications even when you are not in the house. In this situation, you have to use a specialized app for controlling the cooling temperature level and other efficiency criteria of the a/c unit. An ac unit has the ability to do this since it has the ability to procedure signals sent to it from the remote or the cloud web servers.

This signal handling means that there are additional cycles in addition to the thermal cycles of the HVAC system. If a device undergoes such cycles then the opportunities of system failing are substantially high. The reason for this is that such high operating cycles suggests that the digital components will certainly have to handle very high frequencies.

Such high frequencies can not only deteriorate the digital efficiency however likewise add towards sound addition. For that reason, it is empirical that we utilize an air conditioner PCB board which is not prone to effects from such high frequencies. Therefore, High Frequency PCB seems like a great suitable for usage in ac unit. The reason for this is that they come with unique laminates that permit easy operations at high frequencies. In addition to that this special laminate enables far better able to handle the high heat transfer with the PCB board The biggest advantage of using High Frequency PCB is that your air conditioning system will certainly incur minimal sound.

- Rigid PCB. Advanced appliances such as an air conditioning unit involve high-end auto mechanics and also are primarily COOLING AND HEATING systems. So, the parts we make use of in them are usually based on a great deal of thermal stresses. If we make use of a normal PCB in an air conditioner after that chances are that its efficiency will certainly decrease as well as the entire system may break down. An ac unit includes many home heating and cooling down cycles. This means that the regular MOKO Printed Circuit Board Assembly will need to encounter constant thermal growth and also thermal tightening.

Join the Discussion