3D Printing Market Analysis, Trends And Global Outlook In Present World

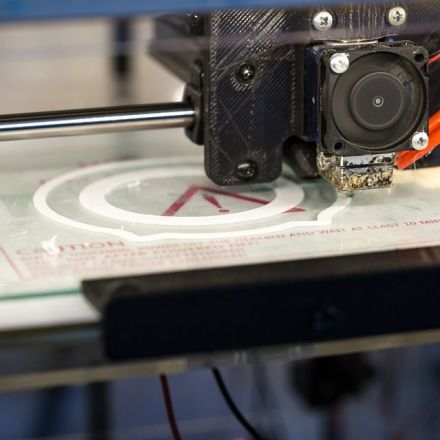

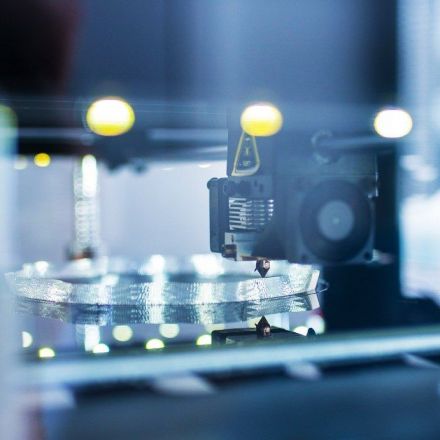

The overall concept of 3D printing is futuristic, facilitating the production of any object in 3 dimensions that can be designed digitally. The technology involves the joining of material added in the form of layers and is also known as additive manufacturing.

-

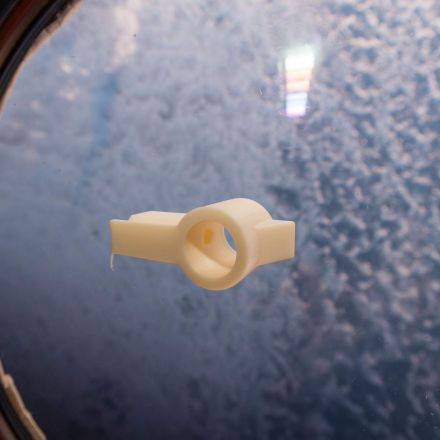

Initially, 3D printing was used mostly for the production of prototypes in a process known as ‘rapid prototyping’, as opposed to making to functional models. However, the technology of 3D printing has evolved considerably over the years, and now can be used to manufacture functional, moving parts. The materials that can be used in 3D printers have also evolved, and now materials such as plastics, metals, nylon, PLA, epoxy resins, wax, polycarbonate, polymers, and even bio-tissues can be used in 3D printing.

Market Analysis

According to the 3D printing market analysis, the applications of 3D printing in the fields of construction, defense and aerospace are growing at a CAGR of 15-25 percent, while its applications in energy and fashion industries are growing at a CAGR of approximately 25-25 percent. In the next 5-10 years, it is estimated that enterprise 3D printing will be realized. By 2020, it’s expected that the first bio-printing will take place for human organs and limbs, and by 2025 there will be 3D manufacturing at an industrial scale. The mass customization ability of 3D printing as well as the variety of materials that can be used are the major driving factors behind the growth of the market.

3D Printing Market Trends

There are several trends in the 3D printing market that have become popular and are making an impact in the field.

SME Consumers

Initially, the use of 3D printers was dominated by larger companies and research institutes, however, recent trends show that more and more small and medium-sized enterprises (SMEs) are now using 3D printing. The drop in prices for 3D printers and their improved availability have made them more accessible for SMEs. In addition, the evolution in technology has made them more useful, moving beyond basic prototypes into fully functioning equipment. For the production of limited quantities of objects, 3D printing is more cost-effective than purchase from original equipment manufacturers (OEM).

Multi-Material Usage

The most common material used in 3D printing is plastic, and although other materials apart from plastics are also used, generally a single type of material is used throughout. The new trend of multi-material 3D printing is challenging the single material concept, by combining the use of more than one material to print a product. The addition of another material to the base material serves to improve the quality of the product, making it sturdier and more reliable, thereby increasing its applications across industries. Especially in heavy-duty industries such as automotive and aerospace, multi-material products are more capable and have a longer life.

Bio-Technology

The technology of 3D printing has the potential to completely revolutionize medical treatment, by producing human veins, arteries, limbs, bones and even organs by using the patient’s own cells. Although the applications of 3D printing in medicine are still in the research phase, if and when the process becomes successful, medical treatment will likely be transformed. Over the years, treatment of organ failure has been treated by means of transplantation, and even bones have been grafted onto patients from cadavers. However, the risk of rejection of the foreign body by the host’s immune system is immense, due to which the person receiving the transplant has to have his or her own immune system suppressed. If the required components are made using the person’s own tissue cells and a 3D printer, risk of rejection will reduce dramatically, boosting chances of success.

Outsourcing

Based on the speed with which technology is evolving, in many cases outsourcing 3D printing services to dedicated service providers becomes a more cost-effective means to access such services, especially for the production of limited items. Apart from the actual 3D printing, designing the product is also a specialized service that often requires separate outsourcing. While the decision to select a supplier of 3D printing services would be based on the materials used for printing, costs and turn around period, the criterion for selecting a designer would be entirely different. The technology of 3D printing is not majorly industry-specific, but the designing process is acutely based on the needs of the specific industry and product, requiring specialized teams.

3D Printing Market Global Outlook

The global outlook for the 3D printing market is immensely positive, as the technology is transferable across the world, and useful in developing and developed economies. In developing nations 3D printing is expected to play an important role in infrastructural development, and urbanization. Since 3D printing drastically reduces the space and time needed to set up manufacturing units, it has valuable potential in emerging economies. Meanwhile, in developed countries, 3D printing is expected to further optimize existing processes while also reducing costs. Research is expected to be another major component of the 3D printing market in developed nations.

An ideal example of futuristic technology, 3D printing has unlimited potential, which will be further realized as the costs involved in 3D printing reduce with time. The vast customization ability of 3D printing makes it ideal for application across industries and the technology is expected to evolve further. While 3D printing is typically used in professional settings currently, its expansion further into commercial uses and eventually into people’s homes is inevitable.

Join the Discussion